Industry News

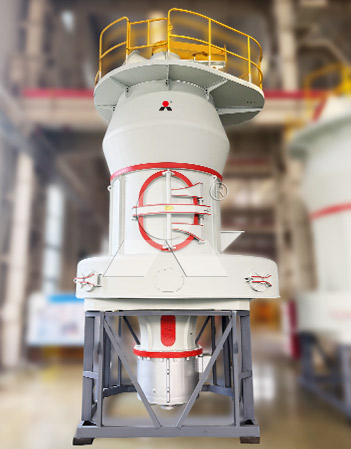

PMD Permanent Magnet Direct-Drive Grinding Mill — 30% Higher Efficiency for Smarter Powder Processing

2026-01-28 09:28:45

We are Liming Heavy Industry, a manufacturer of various types of industrial crushers, such as Raymond Mill, Trapezoidal Mill, Vertical Mill, Ultrafine Mill, Ball Mill, etc.

Our mills can process the following minerals:

limestone, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, etc.

If you need a mill to process stone or minerals into powder, please feel free to contact me (WhatsApp: +86 153 3380 7511). Thank you.

30% Higher Energy Efficiency for Modern Powder Processing

As the powder processing industry continues to face challenges such as high energy consumption, low efficiency, and complex operation management, Liming Heavy Industry introduces thePMD Permanent Magnet Direct-Drive Intelligent European Grinding Mill. By integrating permanent magnet direct-drive technology with intelligent control systems, the PMD series delivers a new benchmark in efficiency, reliability, and smart manufacturing.

Key Specifications

Finished product fineness: 1.6–0.045 mm

Capacity range: 6–55 tons per hour

Applicable materials: Mohs hardness ≤ 7, moisture content below 6%

Suitable for non-flammable and non-explosive materials

Energy efficiency improvement: up to 30%

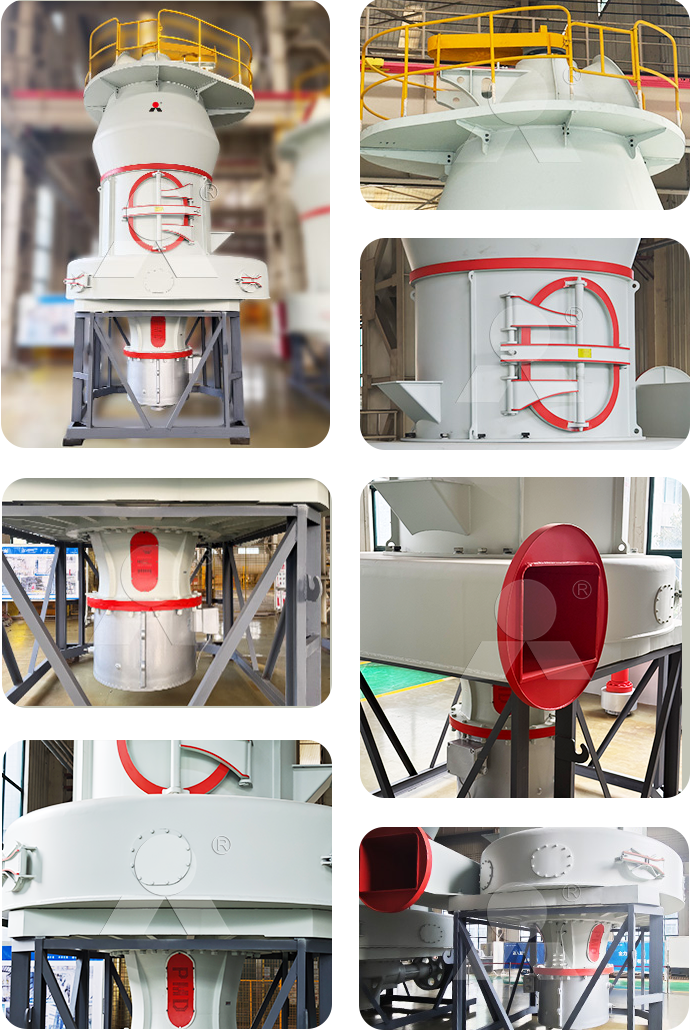

Permanent Magnet Direct-Drive Technology

Traditional grinding mills rely on motors, reducers, and complex transmission systems, which often result in energy loss, frequent maintenance, and unstable operation. The PMD series eliminates intermediate transmission components and applies a permanent magnet direct-drive motor to directly power the main grinding unit.

Power transmission loss reduced by up to 90%

Overall energy efficiency increased by approximately 30%

Transmission system failure rate reduced by 70%

Service life extended by about 50%

The optimized system design further reduces total power consumption by 15%. When combined with a high-efficiency direct-drive fan, additional energy savings of 8–10% are achieved, significantly lowering long-term operating costs.

Intelligent Configuration and Control

The PMD grinding mill is equipped with an intelligent lubrication system, ensuring automatic lubrication of key components such as grinding rollers and classifiers. This enables 24-hour continuous operation without shutdown for maintenance.

A high-efficiency classifier with improved sealing and optimized airflow enhances classification accuracy and increases powder uniformity. The recirculation rate of unqualified particles is significantly reduced.

Multiple sensors installed throughout the equipment monitor temperature, vibration, and pressure in real time, providing early warnings and preventing unexpected downtime.

Remote Monitoring and Smart Management

Through a cloud-based platform and mobile application, operators can remotely monitor equipment status, adjust operating parameters, and start or stop the system without on-site supervision. This reduces labor costs by approximately 30%.

Production data, energy consumption, and product quality records are automatically stored, supporting process optimization and operational transparency.

Environmental Protection and Material Adaptability

The PMD grinding mill operates under a full negative-pressure system and is equipped with a high-efficiency pulse dust collector. Dust emissions remain well below environmental standards, with no secondary pollution.

The system is suitable for processing a wide range of materials, including limestone, quicklime, calcite, gypsum, dolomite, kaolin, barite, and petroleum coke.

Application Industries

Non-metallic mineral powder processing

Flue gas desulfurization for power plants

Clean coal powder preparation

Petroleum coke grinding

New building materials

Chemical raw material fine grinding

Working Principle

Crushed materials are evenly fed into the grinding chamber through a variable-frequency belt feeder. Grinding rollers and rings apply rolling and crushing force to the material. The powder is carried by airflow into the classifier for precise separation.

Qualified powder is collected by the cyclone collector, while oversized particles return to the grinding chamber for further processing. The entire system operates under negative pressure, ensuring clean and dust-free production.

Conclusion

With decades of experience in grinding equipment manufacturing, Liming Heavy Industry continues to drive innovation in intelligent and green powder processing. The PMD Permanent Magnet Direct-Drive Intelligent Grinding Mill represents a major step toward higher efficiency, lower energy consumption, and smarter industrial production.

By delivering customized solutions and strict quality control, we help global customers reduce costs and improve productivity. Liming Heavy Industry remains committed to shaping the future of efficient, environmentally friendly powder processing.

Contact us for a customized solution:

WhatsApp: +86 153 3380 7511

Frequently Asked Questions (FAQ)

1. What makes the PMD grinding mill different from traditional Raymond mills?

The PMD grinding mill adopts permanent magnet direct-drive technology, eliminating gearboxes, belts, and other intermediate transmission components. This significantly reduces energy loss, mechanical wear, and maintenance frequency, resulting in higher efficiency, better stability, and lower operating costs compared with traditional Raymond mills.

2. How does the PMD mill achieve 30% higher energy efficiency?

The efficiency improvement comes from direct power transmission without mechanical losses, optimized system design, and intelligent operation control. By removing gear and belt transmission, power loss is reduced by up to 90% in the drive system, leading to an overall energy efficiency increase of approximately 30%.

3. What materials can be processed by the PMD grinding mill?

The PMD grinding mill is suitable for non-flammable and non-explosive materials with Mohs hardness up to 7 and moisture content below 6%. Typical materials include limestone, quicklime, calcite, gypsum, dolomite, kaolin, barite, and petroleum coke.

4. What is the achievable finished product fineness?

The finished product fineness ranges from 1.6 mm to 0.045 mm. The fineness can be adjusted flexibly by optimizing classifier speed and airflow parameters, allowing the mill to meet diverse application requirements.

5. Can the PMD grinding mill operate continuously?

Yes. The PMD mill is designed for 24-hour continuous operation. Its intelligent thin-oil lubrication system automatically lubricates key components, such as grinding rollers and classifiers, without requiring shutdown for routine maintenance.

6. How does the PMD mill reduce maintenance costs?

By eliminating reducers and belt systems, the PMD mill reduces the number of wear parts and mechanical failure points. The simplified transmission structure lowers maintenance frequency, extends service life, and minimizes unplanned downtime.

7. Does the PMD grinding mill support remote monitoring and control?

Yes. The mill can be integrated with a cloud-based intelligent control platform and mobile application. Operators can remotely monitor operating conditions, adjust parameters, and start or stop the equipment, reducing on-site labor requirements and improving management efficiency.

8. How does the PMD grinding mill meet environmental protection requirements?

The system operates under full negative pressure and is equipped with a high-efficiency pulse dust collector. Dust emissions remain well below environmental standards, with no secondary pollution, making the PMD mill suitable for green and sustainable production projects.