Industry News

Calcium Carbonate Grinding Mill Review for Plastic and Paint Industry in India

2026-01-16 09:14:42

We are Liming Heavy Industry, a manufacturer of various types of industrial crushers, such as Raymond Mill, Trapezoidal Mill, Vertical Mill, Ultrafine Mill, Ball Mill, etc.

Our mills can process the following minerals:

limestone, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, etc.

If you need a mill to process stone or minerals into powder, please feel free to contact me (WhatsApp: +86 153 3380 7511). Thank you.

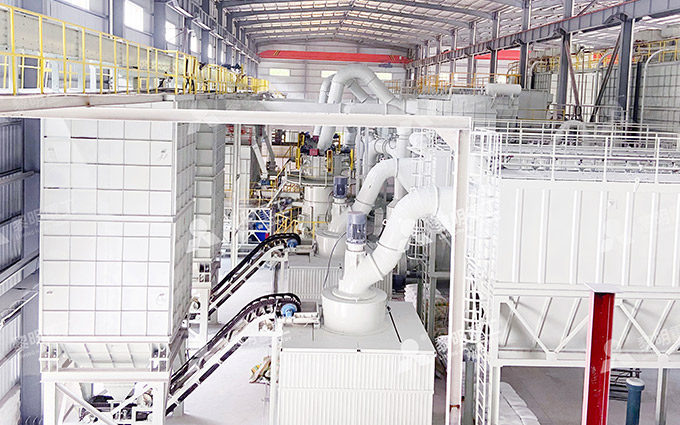

India is currently witnessing a massive industrial expansion, with the plastic and paint sectors standing as two of the fastest-growing industries. Calcium carbonate (CaCO3), also known as Ground Calcium Carbonate (GCC), serves as a critical functional filler in these sectors. For an Indian manufacturer to stay competitive, it is no longer enough to just produce powder; the focus has shifted toward achieving specific particle size distributions, high whiteness, and cost-efficiency. Liming Heavy Industry has emerged as a leading technology partner for Indian enterprises, providing specialized grinding solutions like the LUM Ultrafine Vertical Roller Mill and the MTW European Type Raymond Mill. This review explores how these technologies are revolutionizing calcium carbonate production for the Indian plastic and paint markets.

The Growing Demand for High-Quality GCC in India

The Indian plastic industry, centered in hubs like Gujarat, Maharashtra, and Tamil Nadu, relies heavily on calcium carbonate for the production of PVC pipes, cables, and masterbatches. In these applications, the powder must be fine enough to prevent machine wear and improve the impact strength of the plastic. Similarly, the Indian paint industry, driven by rapid urbanization, requires ultrafine calcium carbonate to enhance the opacity, gloss, and weather resistance of coatings. The traditional ball mill systems are increasingly being replaced by more advanced milling technologies that can deliver d97 and d50 particle sizes with surgical precision while maintaining the high whiteness levels required for premium applications.

LUM Ultrafine Vertical Roller Mill: The Gold Standard for Fine Powders

For Indian manufacturers aiming at the high-end market—such as manufacturers of plastic masterbatches or high-gloss emulsion paints—the LUM Ultrafine Vertical Roller Mill is the premier choice. This machine is specifically designed to produce powders ranging from 400 to 2500 mesh.

One of the primary advantages of the LUM mill is its ability to maintain the whiteness of the calcium carbonate. In traditional grinding, the friction between the grinding media and the material can lead to "graying" of the powder. The LUM mill utilizes a specialized roller and table design that minimizes contact time and heat generation, ensuring that the natural whiteness of Indian limestone (like that found in Rajasthan) is preserved. Furthermore, the integrated multi-head classifier allows for a very narrow particle size distribution, which is essential for uniform dispersion in plastic resins.

MTW Series Raymond Mill: Versatility for Filler Grade Production

Not every application requires ultrafine powder. For general filler grades used in lower-tier paints, adhesives, and rigid PVC pipes, the MTW European Type Raymond Mill offers an unmatched balance of performance and price. This mill is an evolution of the traditional Raymond mill, featuring a bevel gear integral drive and an innovative curved air duct system.

In the context of the Indian market, where operational costs are a major concern, the MTW mill stands out for its low energy consumption per ton of product. It is capable of producing powders from 80 to 425 mesh with high stability. Its compact footprint also makes it ideal for established factories in industrial clusters where space is at a premium. The MTW mill’s ability to run continuously for long periods with minimal maintenance makes it a workhorse for the Indian GCC industry.

Environmental and Economic Impact in the Indian Context

India’s environmental regulations, particularly regarding dust emissions in industrial zones, have become significantly stricter. Liming’s grinding systems address this by operating under a negative pressure environment. This ensures that no dust escapes into the factory atmosphere. Coupled with high-efficiency pulse jet dust collectors, these mills allow Indian factories to operate in compliance with local pollution control board standards.

From an economic perspective, the shift from traditional wet grinding to dry grinding with mills like the LUM series has saved Indian manufacturers significant costs in drying and logistics. By producing a dry, ready-to-use powder, manufacturers can supply directly to plastic and paint compounding plants, streamlining the supply chain.

Comparison Table: LUM vs. MTW for Calcium Carbonate

| Feature | LUM Ultrafine Vertical Mill | MTW Raymond Mill |

|---|---|---|

| Target Fineness | 400 - 2500 mesh | 80 - 425 mesh |

| Best Use Case | High-end Paint, Plastic Masterbatches | General PVC Pipes, Primer Paints |

| Energy Consumption | Very Low per unit of surface area | Low for medium fineness |

| Whiteness Preservation | Superior | Excellent |

Why Liming Heavy Industry is Recommended

_1767930326611.jpg)

Choosing Liming Heavy Industry as a supplier for the Indian market provides several strategic advantages. Firstly, the technology is proven across thousands of installations worldwide. Secondly, Liming offers comprehensive localized support. From the initial testing of limestone samples to the final commissioning of the plant, Liming's engineering team provides a turnkey solution that reduces the technical burden on the buyer.

For Indian entrepreneurs, the "total cost of ownership" is the most important metric. Liming mills are designed with wear-resistant parts that have a longer lifespan than generic alternatives, directly translating to fewer replacements and less downtime. As the Indian plastic and paint industries continue to move toward higher quality standards, the transition to Liming’s grinding technology is an essential step for any forward-thinking producer.

Conclusion

The manufacturing of calcium carbonate for the Indian plastic and paint industries has moved beyond simple crushing. Modern applications demand precision, efficiency, and purity. Whether it is the LUM Ultrafine Vertical Mill for high-tech polymer additives or the MTW European Type Raymond Mill for versatile filler production, Liming Heavy Industry provides the tools necessary to thrive in India's competitive landscape. By investing in these advanced grinding solutions, Indian processors can ensure they deliver products that meet both domestic demands and international quality standards.

_1761355701097.jpg)

Frequently Asked Questions (FAQ)

1. Which mill is best for producing 1500 mesh calcium carbonate for the paint industry?

The LUM Ultrafine Vertical Roller Mill is the ideal choice for 1500 mesh requirements, as it is specifically designed for ultrafine powder production with high whiteness and consistent particle size.

2. Can these mills handle the hard limestone found in Rajasthan?

Yes, both the MTW and LUM mills are engineered to process materials with Mohs hardness up to 9. The limestone typically found in India is well within the operating parameters of these machines.

3. How does Liming ensure the powder doesn't get contaminated during grinding?

The LUM and MTW mills use high-quality, wear-resistant alloys for the rollers and plates. The design minimizes metal-to-metal contact, preserving the purity and whiteness of the calcium carbonate.

4. Is the MTW mill more energy-efficient than a traditional ball mill?

Yes, the MTW series can be up to 20-30% more energy-efficient than ball mills for medium-fine powder production because it combines grinding and classifying in one step with a more direct drive system.

5. What kind of dust control do these mills have?

They use a closed-circuit system with a high-efficiency pulse jet dust collector. This ensures that the air discharged is clean and the factory environment remains dust-free, complying with Indian environmental laws.

6. Does Liming provide installation services in India?

Yes, Liming has experienced engineers who provide on-site installation, commissioning, and training services for workers in India.

7. How often do the grinding rollers need to be replaced?

Depending on the material hardness and operating hours, rollers usually last between 8,000 to 12,000 hours of operation before needing significant maintenance or replacement.

8. Can the fineness of the powder be changed easily?

Yes, the fineness is controlled by an automated classifier. You can adjust the speed of the classifier through the PLC control system to easily switch between different powder grades.

9. Is a separate dryer needed if the limestone is slightly damp?

The LUM Vertical Mill can use hot air to dry materials with up to 15% moisture during the grinding process, often eliminating the need for a separate pre-dryer.

10. What is the typical lead time for delivering a mill to India?

Production usually takes 30-45 days, and shipping to major Indian ports like Mundra or Nhava Sheva takes an additional 15-25 days.

11. Are spare parts for Liming mills readily available in the Indian market?

Liming maintains a reliable supply chain and often works with local representatives to ensure that wear parts and critical spares are available for quick delivery in India.

12. What size of raw material can the MTW mill accept?

The MTW mill can typically accept raw limestone with a feed size of up to 30mm to 50mm, depending on the specific model size.

13. Can these mills be used for other minerals besides calcium carbonate?

Absolutely. They are highly versatile and can be used for grinding marble, talc, barite, dolomite, and many other non-metallic minerals used in various industries.