Industry News

Carbon Black Grinding Mill for the Rubber and Tire Industry – Where to Buy the Cheapest Supplier in Japan

2025-12-17 08:50:45

We are Liming Heavy Industry, a manufacturer of various types of industrial crushers, such as Raymond Mill, Trapezoidal Mill, Vertical Mill, Ultrafine Mill, Ball Mill, etc.

Our mills can process the following minerals:

limestone, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, etc.

If you need a mill to process stone or minerals into powder, please feel free to contact me (WhatsApp: +86 153 3380 7511). Thank you.

Carbon black is a fundamental material in Japan's rubber and tire industry. It is used to enhance tensile strength, improve abrasion resistance, increase durability, and reinforce structural integrity in a wide range of rubber-based products. As Japan's automotive and industrial rubber sectors continue to expand, the demand for high-quality, ultrafine carbon black powder has grown rapidly. To achieve consistent product performance, manufacturers require an efficient grinding system capable of producing ultrafine and contamination-free carbon black powder. This is where a professional carbon black grinding mill becomes essential.

In tire manufacturing, carbon black acts as both a reinforcing agent and a performance enhancer. The quality of the carbon black powder directly influences tire wear resistance, rolling performance, heat dissipation, and lifespan. In the rubber industry, ultrafine carbon black ensures uniform dispersion, improves elasticity, and boosts mechanical properties. Because these applications require precise control over particle size—often between 200 mesh and 2500 mesh—the choice of grinding mill can greatly affect final product quality.

Why Ultrafine Grinding Is Essential for Carbon Black

Carbon black particles have a naturally small size, high surface area, and porous structure, but mechanical grinding is still required to achieve the ultrafine powder standards required by high-end rubber and tire applications. Processing carbon black poses specific challenges due to its characteristics:

Soft and lightweight particles that tend to float and agglomerate

High oil absorption and strong adsorption properties

Strong tendency to generate dust during handling

Requirement for uniform fineness for controlled reinforcement performance

To overcome these challenges, a grinding machine must provide stable particle size distribution, sealed and dust-free operation, and high classification accuracy. Traditional mills often fail to deliver the fineness and cleanliness required. As a result, rubber and tire manufacturers in Japan increasingly turn to modern ultrafine grinding mills.

MW Micro Powder Mill for Ultrafine Carbon Black Processing

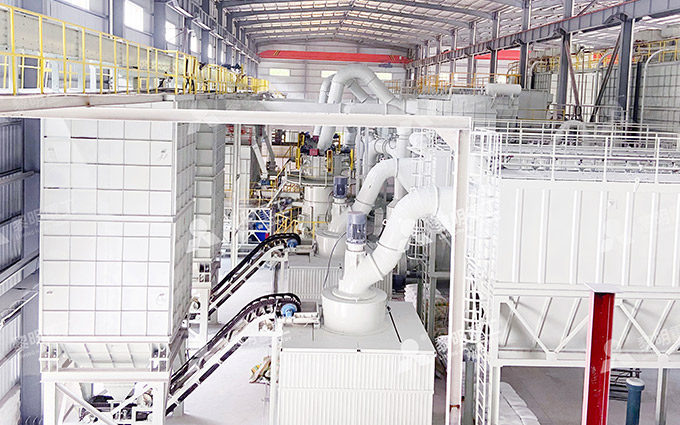

For Japanese manufacturers seeking a reliable solution for carbon black grinding, the MW micro powder mill stands out as an efficient and cost-effective choice. Its design integrates crushing, grinding, and classifying into one system, enabling stable production of ultrafine powders ranging from 325 mesh to 2500 mesh—ideal for advanced rubber and tire applications.

Key advantages include:

High fineness output for superior carbon black reinforcement performance

Efficient dust collection to maintain a clean and safe production environment

Low energy consumption through optimized structural design

Automated classification for precise control over particle size

Stable operation with low vibration and reduced maintenance

The MW micro powder mill is particularly suitable for carbon black because of its ability to handle soft materials with low hardness while maintaining consistent ultrafine output. The combination of grinding rollers, rings, and high-efficiency classifiers ensures uniform dispersion, making it easier for manufacturers to incorporate carbon black into rubber compounds. This directly improves product performance and consistency in Japan's tire factories and rubber plants.

Applications in Japan's Rubber and Tire Sector

Japan is home to some of the world's leading tire manufacturers, as well as numerous mid-sized and specialized rubber product producers. These industries require stable, ultrafine carbon black powder for a wide range of applications:

Passenger vehicle tires and high-performance tires

Industrial conveyor belts and rubber hoses

Anti-vibration rubber components for automotive systems

Rubber seals and gaskets

Elastomer compounds requiring uniform and high-strength reinforcement

High-end products such as low-rolling-resistance tires rely heavily on precise carbon black fineness to achieve optimal dispersion. A reliable ultrafine grinding mill helps Japanese manufacturers maintain strict quality control while lowering production cost.

Where to Buy the Cheapest Carbon Black Grinding Mill in Japan

Many Japanese companies seek cost-effective equipment without compromising quality. Due to local manufacturing costs and import markups, grinding mills sold directly within Japan often come at a higher price. A practical solution is to source advanced carbon black grinding equipment from established international manufacturers with proven expertise.

Liming Heavy Industry offers an excellent balance of performance, durability, and competitive pricing. The MW micro powder mill provides a high-quality option for Japanese buyers seeking affordable ultrafine grinding equipment. Companies purchasing directly from the manufacturer enjoy favorable factory pricing and reliable technical support.

With strong global experience and successful installations across Asia, this supplier offers one of the most cost-efficient choices for carbon black processors in Japan. High output, low operating cost, and stable ultrafine powder quality make the MW micro powder mill a dependable choice for tire and rubber producers looking to upgrade their grinding systems.

FAQ

What fineness can the MW micro powder mill achieve for carbon black?

It can produce ultrafine powder ranging from 325 mesh to 2500 mesh, suitable for high-end rubber and tire applications.Is the MW mill suitable for continuous production?

Yes, it provides stable operation with low vibration and efficient dust control, ideal for long-term industrial use.Why is ultrafine carbon black important for tire manufacturing?

Ultrafine carbon black improves dispersion, enhances reinforcement, and boosts mechanical performance.Can this grinding mill help reduce production costs?

Yes, the MW micro powder mill offers low energy consumption and long service life of wearing parts, reducing overall operational cost.Is the equipment cost lower when buying directly from the manufacturer?

Direct purchase offers factory pricing, making it more affordable than typical suppliers within Japan.