Industry News

Limestone Micro Powder Grinding Mill with Dust-Free Operation

2025-10-09 05:59:26

We are Liming Heavy Industry, a manufacturer of various types of industrial crushers, such as Raymond Mill, Trapezoidal Mill, Vertical Mill, Ultrafine Mill, Ball Mill, etc.

Our mills can process the following minerals:

limestone, quicklime, kaolin, talc, barite, bentonite, calcium carbonate, dolomite, coal, gypsum, clay, carbon black, slag, cement raw materials, cement clinker, etc.

If you need a mill to process stone or minerals into powder, please feel free to contact me (WhatsApp: +86 153 3380 7511). Thank you.

Limestone is one of the most important raw materials in industries such as construction, chemicals, metallurgy, and environmental protection. When processed into fine and ultra-fine powders, it is widely used in producing desulfurization absorbents for power plants, fillers for plastics and coatings, as well as raw materials for cement and glass. To meet the growing demand for high-purity and fine-grade limestone powder, efficient and environmentally friendly grinding technology is essential.

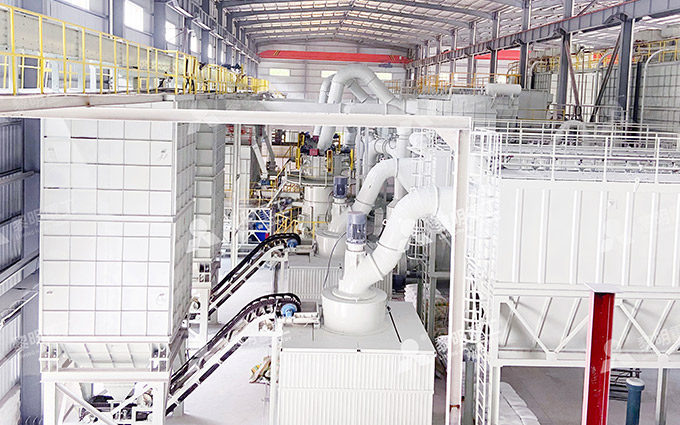

The micro powder grinding mill has become a preferred solution for limestone processing. Unlike traditional milling equipment, a micro powder mill is designed to produce powder with fineness ranging from 325 mesh up to 2500 mesh. This ultra-fine grinding capability ensures limestone powder meets the strict requirements of high-end applications in industries such as coatings, paints, paper, and rubber. The uniform particle size distribution also improves the performance of final products while reducing material waste.

A major advantage of modern limestone micro powder mill is their dust-free operation. Equipped with advanced pulse dust collectors and sealing systems, these mills effectively capture fine particles during the grinding process, ensuring a clean working environment and compliance with environmental regulations. This feature not only protects workers' health but also reduces powder loss, leading to higher efficiency and cost savings.

Energy efficiency is another key benefit. Micro powder mills integrate grinding, classifying, and collecting in a single system, reducing energy consumption while maintaining high output. Automatic control systems allow stable operation and precise fineness adjustment, enabling continuous and reliable production. These advantages make micro powder grinding mills highly suitable for large-scale industrial applications.

Liming Heavy Industry provides advanced limestone micro powder grinding mills designed for high efficiency, energy savings, and dust-free operation. With years of expertise and proven performance in the field of ultra-fine grinding, Liming's equipment ensures consistent product quality, long service life, and reduced maintenance costs. For industries seeking environmentally friendly and reliable limestone powder production, Liming's micro powder mills are a dependable choice.

FAQ

Q1: What is the typical fineness range of limestone micro powder mills?

A: They can produce ultra-fine powder from 325 mesh up to 2500 mesh, suitable for high-end applications.

Q2: Why is dust-free operation important in limestone grinding?

A: It protects workers' health, meets environmental standards, and reduces powder loss during production.

Q3: How does micro powder grinding technology improve efficiency?

A: By combining grinding, classifying, and collecting in one system, it reduces energy use and increases output stability.

Q4: What advantages do Liming Heavy Industry's micro powder mills offer?

A: They deliver dust-free operation, energy efficiency, precise fineness control, and long-term reliable performance.